Labor, food costs and efficiency: The financial urgency of food waste prevention in 3 charts

The two biggest costs a foodservice operation contends with -- food and labor -- are both way up. The recovery from COVID is unsteady and unpredictable due to the Delta variant. At a time when kitchen staff are being asked to do even more with even less, the typical foodservice operation continues to waste 4% to 10% of the food it purchases.

You simply can’t afford that level of waste and inefficiency, particularly right now. Here are 3 charts to help explain why.

#1. The food your kitchen is wasting is even more expensive than just a few months ago.

Food costs fluctuate, and often rise. But now they are surging globally. So at the same time a kitchen is paying more to bring food into the operation, it is paying more for the food it wastes. The most recent figures from the United Nations Food and Agriculture Organization (below) show global food prices have risen by 31% over last year. Despite a recent click downward, you’d have to go back nearly a decade to find the price index this high.

Global food cost changes year to year. Food costs have risen 31% over the past year.

Food waste prevention helps: Leanpath clients prevent 50% of their food waste on average, leading to a reduction in food purchases of 2%-6%. This also leads to reductions in energy costs to prepare that food and hauling fees to dispose of the waste.

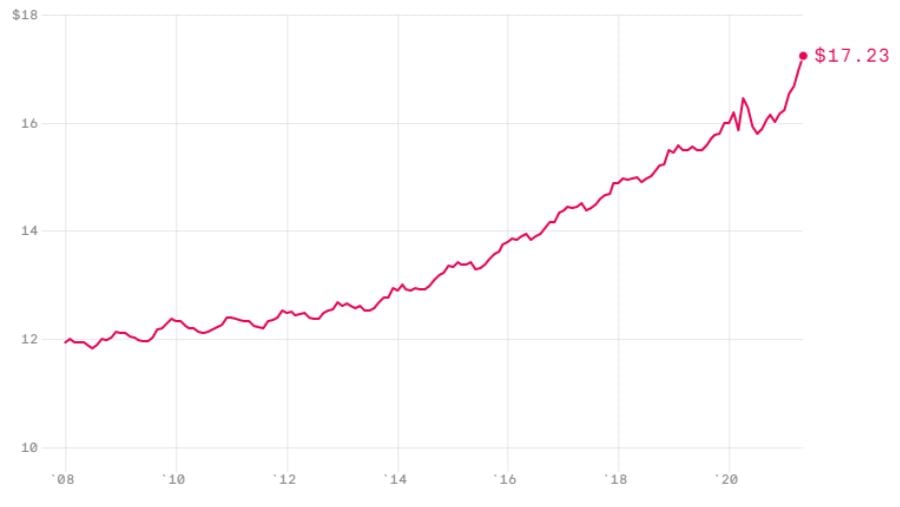

#2. The labor used to prepare that wasted food is more expensive too.

Food waste is inextricably linked to wasted labor: spending staff time inventorying food that only gets thrown out; overproducing food that doesn’t get eaten; etc. And right now that wasted labor is costing more than ever. Major economies around the world are experiencing historic labor shortages, which are driving the cost of labor higher. The chart below from the US Bureau of Labor Statistics shows the increase in average hourly wages for US foodservice workers. It captures the reality around the world.

Change in average U.S. hourly rate for foodservice workers. A labor shortage is impacting the globe.

Food waste prevention helps: Over half of the food waste in most kitchens is due to overproduction, the most glaring example of food waste leading to wasted labor. If you cut waste from overproduction in half, the labor savings could increase your kitchen’s profitability by 4% to 8%, according to Leanpath analysis.

#3. As volumes continue to remain below pre-COVID levels, efficiency is lowered and waste increases.

According to Leanpath data, as volumes decrease--as we’ve seen happen as a result of COVID--the percentage of food waste increases. The analysis of Leanpath data is based on a metric called the Food Efficiency Ratio, or FER, which measures the percentage of food purchases that are wasted. A lower FER means you are wasting less of the food coming in the kitchen’s back door, and are thus more efficient. When volumes decrease, the percentage of that food going to waste increases. The kitchen becomes less efficient. In the chart below you see as volumes decrease (from left to right) the indexed amount of food waste increases (bottom to top).

As food volume decreases (left to right) the percentage of food waste increases.

Food waste prevention can help: The first step in preventing food waste is measuring that waste, so you know what is being wasted and why. That allows kitchens to make smart decisions in purchasing and prep to avoid that waste going forward. That food waste data is collected in real time and provides one of the few leading indicators of how accurate, for instance, your production sheets are as volumes fluctuate. You are able to remain responsive and agile to changing volumes as the industry continues to build back from the pandemic.

The financial benefit of food waste prevention has been validated far beyond Leanpath’s analysis. Recent research by the UN-affiliated organization Champions 12.3 found an average 7:1 ROI from food waste prevention. The U.S.-based advocacy organization ReFED looked at various ways to address food waste and determined that food waste tracking (the first step in food waste prevention) provides the foodservice industry the greatest financial benefit of any solution, to the tune of $2.72 billion.

The financial urgency--and opportunity--of food waste prevention is clearer than it’s ever been.

Sign up for our monthly newsletter in the footer below for the latest in

food waste prevention initiatives, best practices, webinars and more.