When food is wasted, labor is wasted - Prevent Food Waste

Food waste is a $1 trillion global problem. And roughly one quarter of that waste is coming from foodservice--a significant source of lost profits for the industry.

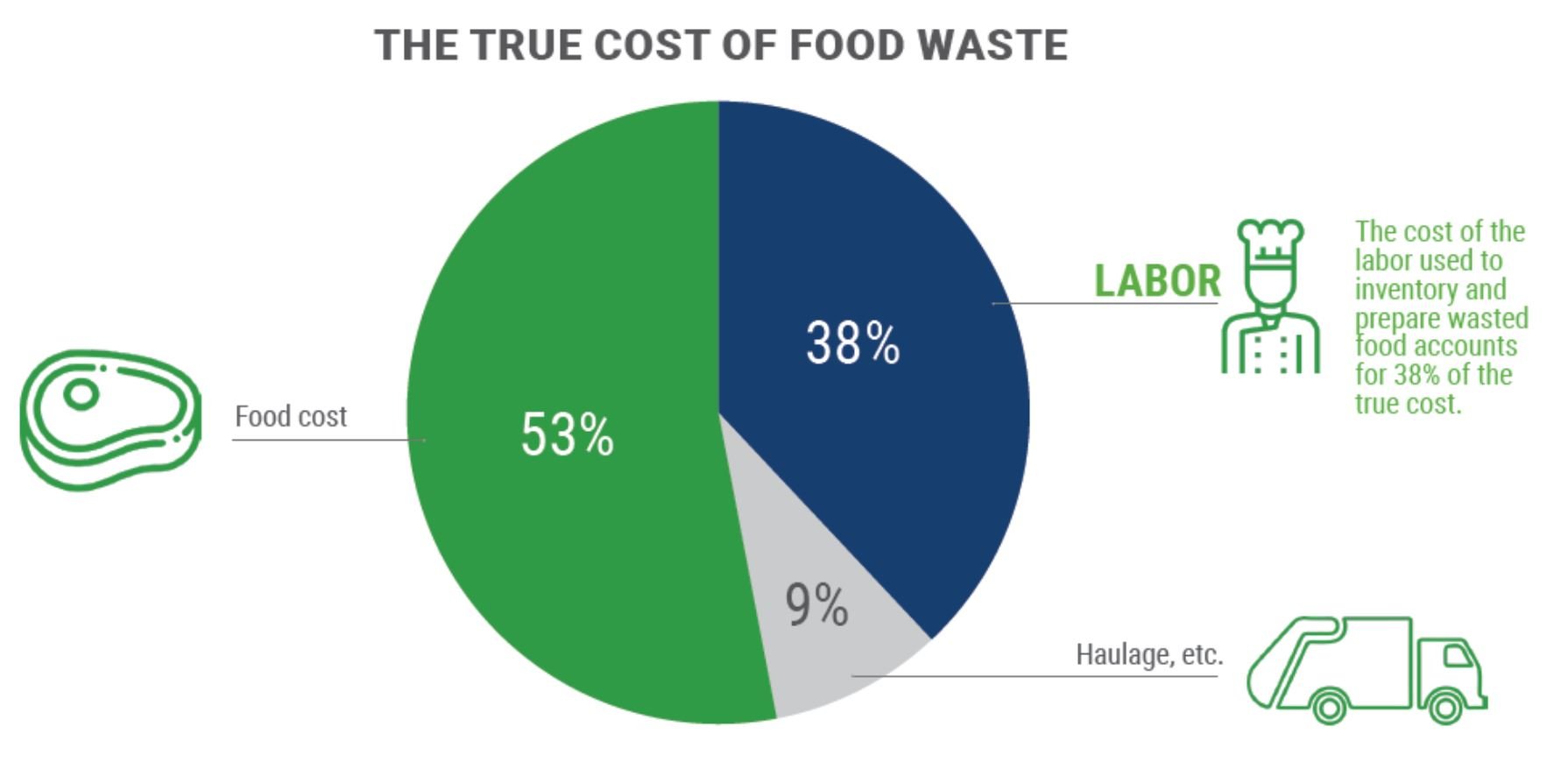

The cost of food waste is typically equated with the purchase cost of that wasted food, which makes sense. But the true cost of food waste has to also factor in the cost of the labor used in inventorying, preparing, serving and ultimately discarding that food waste.

Right now, the world is experiencing a massive labor shortage, the impact of which is falling particularly hard on foodservice. It is a time to remain vigilant about food waste. Because when labor is tight, the pain is particularly acute when a kitchen dedicates staff time prepping food that only goes to waste.

The U.K.-based food waste research and advocacy organization WRAP released a report in 2018 estimating the true cost of food waste in foodservice operations. Factoring in staff time and ancillary expenses, the true financial burden of waste is nearly twice the cost of the food itself.

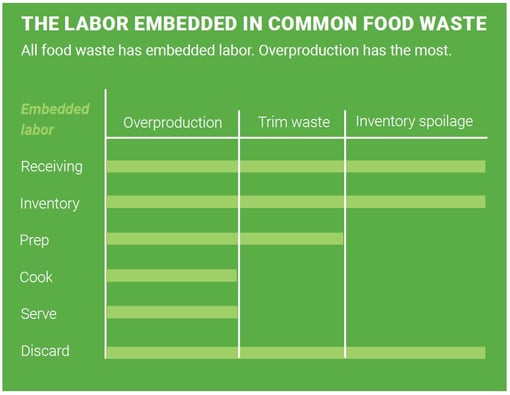

Overproduction is typically the top driver of food waste in the organizations we partner with at Leanpath. Most organizations are wasting between 4 and 10 percent of the food they purchase, and as much as half or more of this is usually from overproduction (preparing excess food that either doesn’t or can’t get repurposed).

Understanding the oversize role overproduction plays in food waste is important because, while all food waste has embedded labor, overproduction has the most. So the source of the most food waste in the typical kitchen is also the source of the most wasted labor.

When a kitchen prevents food waste—actually stops it from occurring in the first place—it stops purchasing and prepping food that it knows will only go to waste. And it stops wasting the embedded labor.

Leanpath analysis found that when a kitchen can cut overproduction in half, it is likely to see a 4-8% increase in profitability from labor savings alone, without even factoring in savings from food costs.

The most effective way to prevent food waste, especially from overproduction, is through food waste tracking. The data gathered through daily tracking allows foodservice operations to understand what is being oveproduced and to prevent that waste going forward.